Parachute riggers have a broad range of responsibilities that include facilities and equipment, performance standards, records, and use of their seal. The following describes the responsibilities of a certificated parachute rigger.

FACILITIES AND TOOLS

Issuance of a parachute rigger certificate is just the first step toward becoming a professional parachute rigger. As the uncertificated person gains experience packing, he or she should also begin to acquire an inventory of tools and manuals necessary to exercise the privileges of a certificate. In compliance with 14 CFR, section 65.127, there are several items necessary before the parachute rigger can exercise the privileges of his/her certificate. One of these requirements is a smooth table top that is at least 3 feet wide by 40 feet long; however, this is necessary only if the parachute rigger is going to pack round parachutes. With square reserve parachutes gaining widespread use in the skydiving community in recent years, some parachute riggers are specializing in packing only square reserve parachutes. A table can be used for packing this type of parachute, but the manufacturer may specify any smooth, clean surface with a size that accommodates the canopy. In this case, a clean, carpeted floor will do the job and a table may not be necessary. According to 14 CFR, subsection 65.127(b), the parachute rigger needs suitable housing that is adequately heated, lighted, and ventilated for drying and airing parachutes. This is subject to interpretation by the parachute rigger and the Administrator since the standards fluctuate based on location and time of year.

A parachute rigger must have enough tools and equipment to pack and maintain the types of parachutes for which he/she is rated to service. This may include only the basic tools of a packing fid, temporary pin, and pullup cord if this is all that the manufacturer says is necessary to pack its product. However, there is a broad selection of tools necessary for a well-equipped parachute rigger to possess. These are covered in detail in

Hand Tools,

Sewing Machines, and the

Parachute Loft.

PERFORMANCE STANDARDS

A number of performance standards are defined in 14 CFR, section 65.129 to guide the parachute rigger’s performance of the duties that fall under the certificate. The parachute rigger may not:

- Pack, maintain, or alter any parachute unless he/she is rated for that type.

- Pack a parachute that is not safe for emergency use.

- Pack a parachute that is not thoroughly dried and aired.

- Alter a parachute in a manner not specifically authorized by the Administrator or the manufacturer of the parachute.

The last item in this list is one that has been abused by many master parachute riggers over the years. The master parachute rigger must have Administrator or manufacturer approval, in writing, to be in compliance with this regulation.

Aside from the necessary tools, 14 CFR, subsection 65.129(f) states that parachute riggers may exercise the privileges of the certificate only if they understand the current manufacturer’s instructions for the operation involved. This means that parachute riggers must possess a copy of the instructions or have access to them during the operation. If they do not have a copy, but the owner of the parachute provides them, then the parachute rigger may pack or maintain the parachute.

A variation on this theme is accessing the packing instruction via the Internet. Many manufacturers provide manuals via their Web sites. If the parachute riggers do not download the actual instruction, they must show that they had access during the packing of the parachute. For example, a laptop computer may not have a printer attached, but could still meet this requirement.

Parachute riggers are not necessarily required to download the instructions to a hard drive or disk as long as they are able to access the manual in real time. However, if a problem is identified with the parachute rigger’s pack job at a later date, the parachute rigger would need to prove to the Administrator that he/she had access to the instructions. Without a hardcopy or downloaded computer files, it would appear that the parachute rigger had not met the rule requirement.

CURRENCY REQUIREMENTS

Once an individual obtains a parachute rigger certificate, it is valid for life unless surrendered, suspended, or revoked. If the individual intends to work as a parachute rigger and not just have the certificate, it is necessary that he/she maintains currency as a practicing parachute rigger. These currency requirements include at least one of the following.

- Performing parachute rigger duties for at least 90 days within the preceding 12 months.

- Demonstrating to the Administrator the ability to perform those duties.

RECORD KEEPING

Maintaining proper records of parachute rigger activities is an important responsibility. This is necessary for the protection of the parachute rigger, the user of the parachute, and the satisfaction of the Administrator. Under 14 CFR, section 65.131, certificated parachute riggers must document the packing, maintenance, and alteration of parachutes they have performed or supervised. These records normally are documented in a parachute rigger’s logbook. The following information must be documented:

- Parachute type and make.

- Serial number.

- Name and address of the owner.

- Kind and extent of work performed.

- Date and location of work performed.

- Results of any drop tests.

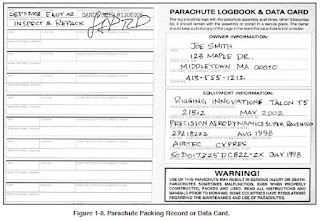

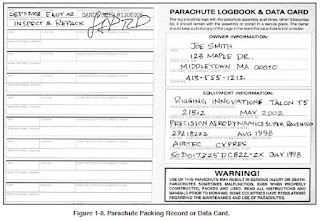

These records must be kept for a minimum of 2 years. Figure 1-7 shows a sample of a logbook page. In addition, each parachute rigger must note on the parachute packing record or data card [Figure 1-8] the following information.

- Date and location of packing.

- A notation of any defects found on inspection.

- Parachute rigger certificate number.

- Parachute rigger name and signature.

While not required on the data card, it has become commonplace for the parachute rigger to note the work performed as well. This is usually noted as A & P for assemble and pack or I & R for inspect and repack. Professional parachute riggers often use an ink stamp on the data card that indicates name, certificate number, seal symbol, and provides an area for signature. This allows the customer or other parachute riggers to read the name (some signatures are illegible) and to correlate the last entry with the seal on the parachute.

SEALING THE PARACHUTE

As noted previously, each certificated parachute rigger is issued a seal symbol with which each parachute is sealed once he/she packs it in a manner prescribed by the manufacturer. This ensures that no one tampers with the parachute and the owner knows that it is ready for use.